In depth listening to the client's request

Visionar’s operational flow is structured in precise and customer-centric phases:

Design

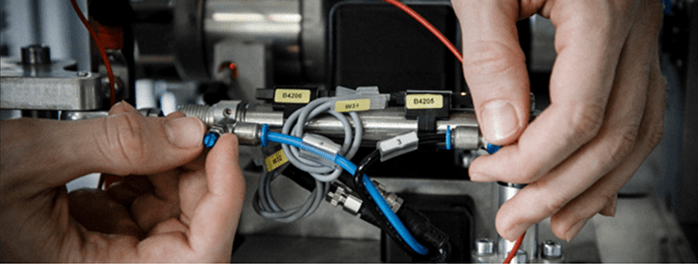

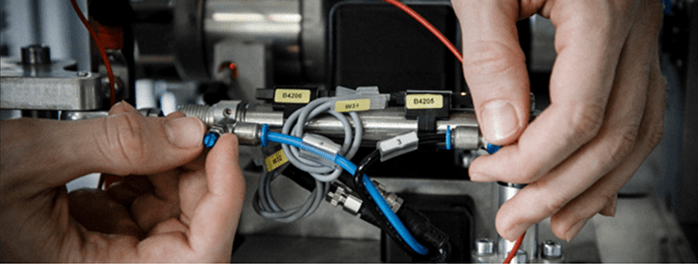

Execution

Debug & Turning

Distinctive Skills

Our highly qualified technical team develops internally

Mechanical, electrical, electronic and software designQuality and advanced technical assistance

Assembly and testingAnalysis and simulation (FEM, CFD, Matlab)

Distinctive Skills

Mechanical, electrical, electronic and software designAssembly and testing

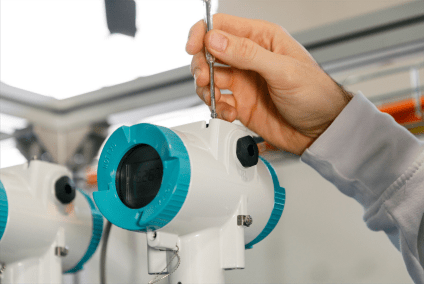

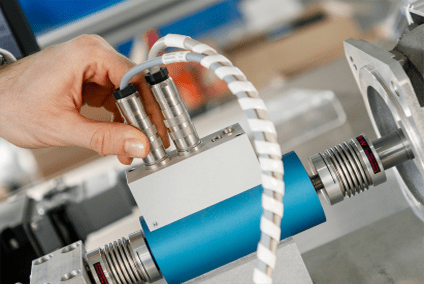

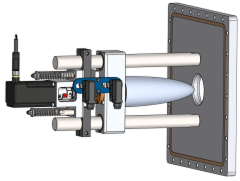

– We develop and manufacture multifunctional testing and control systems able to deploy several tests in parallel. Our testing systems are equipped with technologies enabling the management of high complexity in terms of final product codes and requirements.

– The software applications controlling our testing systems allow the interconnection with the ERP (I4.0) and produce custom-tailored reports.

– We developed a solid experience in testing for many products including gear motors, electric motors, pumps, boilers, fans, blowers, automotive components and fluid dynamics elements.

– We develop internally the whole project to provide our Customers with turnkey solutions and services.

– We internally assemble and certify our test benches.

Distinctive Skills

Mechanical, electrical, electronic and software designAssembly and testing

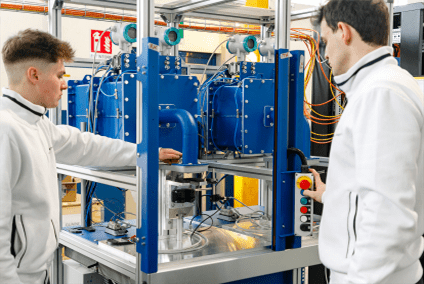

Our testing systems are widely employed in:

– Quality

(incoming tests, statistical tests, endurance tests, after sale returns)

– Laboratory

(performance characterization, product development tests)

– End-line tests

Distinctive Skills

Mechanical, electrical, electronic and software designAssembly and testing

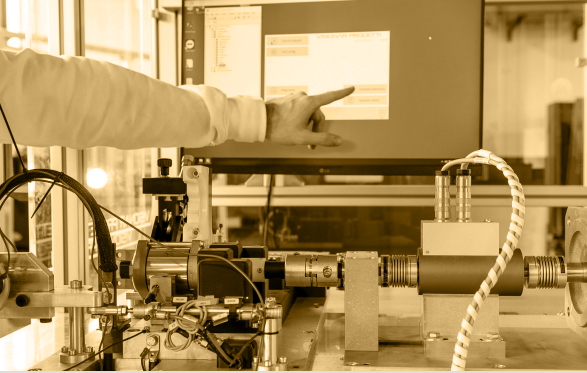

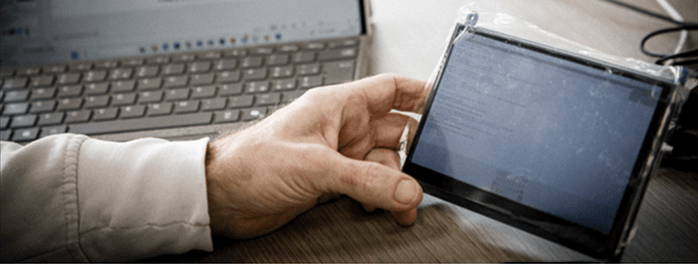

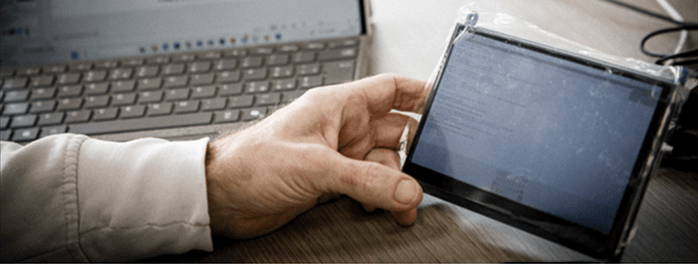

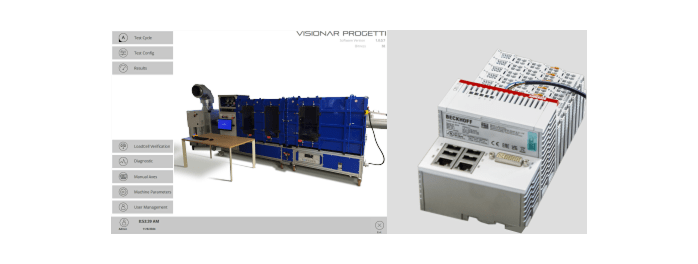

Examples of User Interfaces

of test bench management software

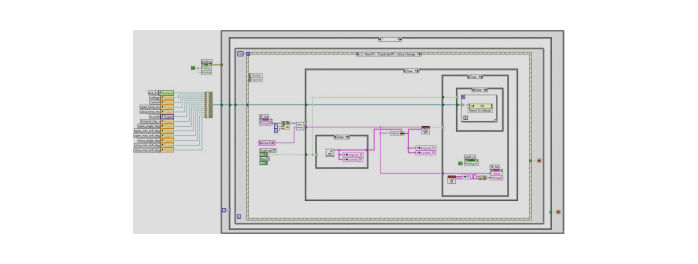

We develop the management interfaces for our testing systems on PC, at higher level, in Labview. Starting from a common structure, the user interfaces can be customized according to specific Customer needs.

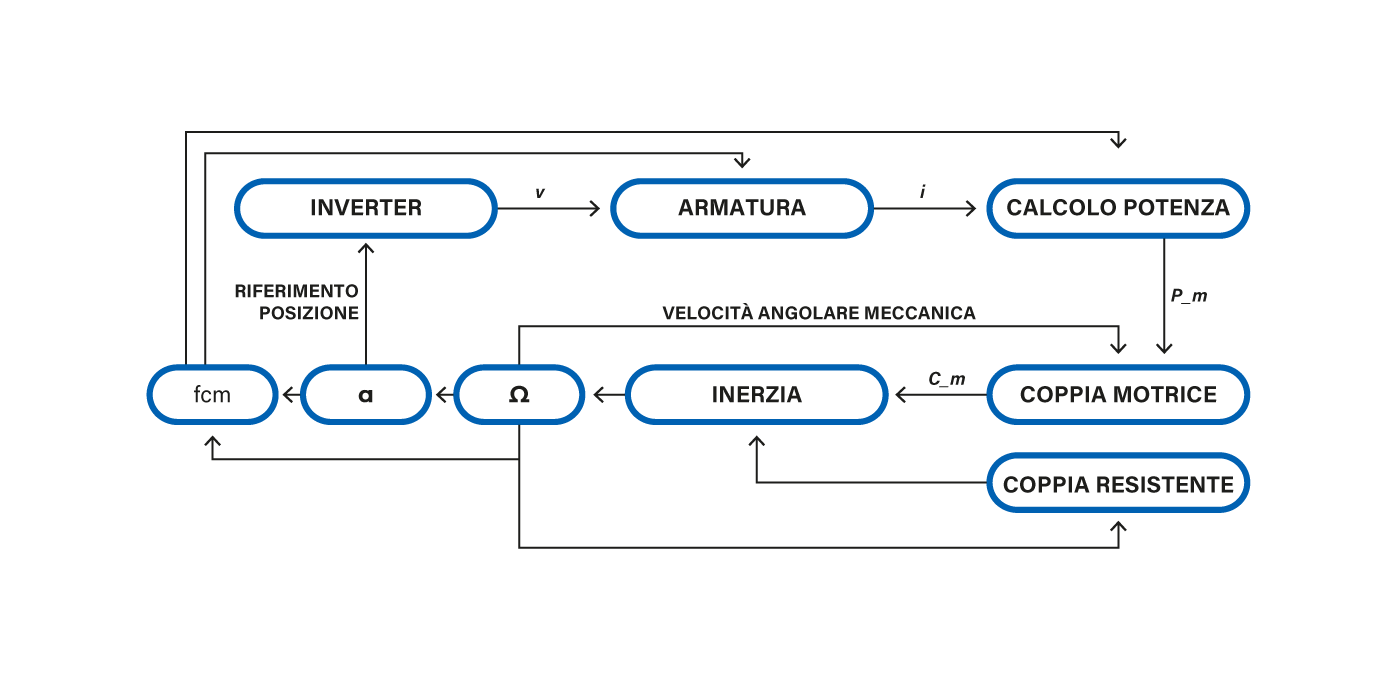

On lower level we develop application on PLC with high calculation performances in order to have real-time control and data acquisition, necessary when dynamic of DUT are important and useful to have synchronous data management.

Distinctive Skills

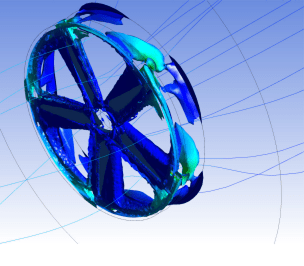

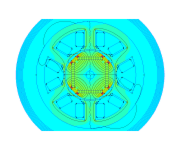

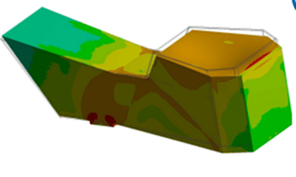

Analysis and simulation (FEM, CFD, Numeric Computing Platform)

We use different calculation and simulation systems in our development process:

– Solid Works integrated Mechanical and Electrical design –FEM structural simulations –Fluid dynamics simulations–Modal and vibrational analysis–Matlab simulations

– CFD simulations

– Electromagnetic simulations

– Numeric Computing Platform Simulations

– SolidWorks Design

– FEM structural simulations

Distinctive Skills

Quality and advanced technical assistance

Visionar develops and produce its machines and assure an efficient and comprehensive after sale program.

After installation, approval and training, the Customer is assisted in case of need in different ways:

– Remote connection

– Providing spare parts and servicing instructions

– Direct assistance on the field

For each testing system, the After Sale Manager will assist the Customer according to the kind of request.