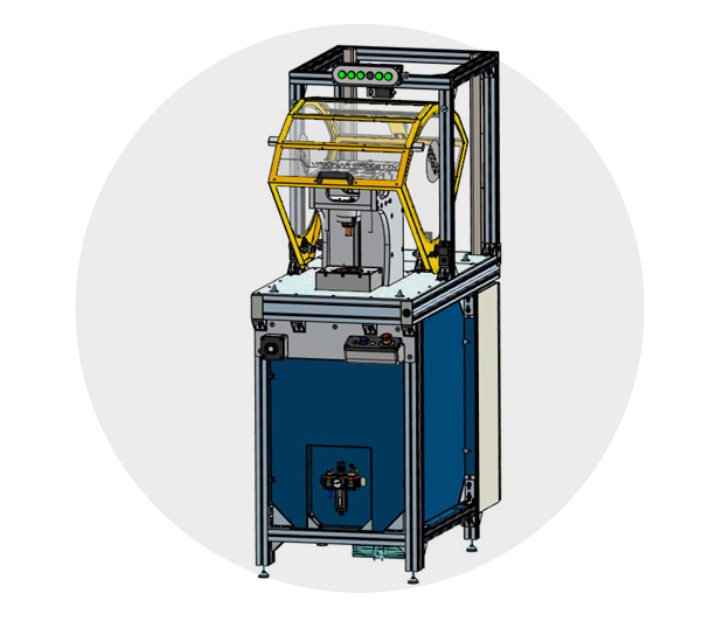

Sistema di piantaggiocuscinetto con misuraforza-spostamento

Features:

Bearing planting system with real-time force and displacement meas urement, ok-nok control integration on the initial, medium and final values of force and displacement, autosetting of the strokes in the event of code change. The system is connected to a remote line control PC for the management of the test plans.

Customer needs:

Have a system that allows to exert forces of the order of 200kg to be able to press-fit bearings onto fractional electric motor shafts. Be able to independently set the value of the press-fit height, the forces to be measured correlated with displacement.

Solution:

System created using a numerically controlled electric press with integrated displacement and force measurement. Integration to the production line using a control PLC that connects via Ethernet to the line control PC for managing work recipes. The equipment is also equipped with a QRcode scanner for tracking machined pieces.